The best tool I own is probably my Lie-Nielson block plane. I've been taking some time lately to hone my sharpening skills and encountered the idea of building my own hand planes. It's a very attractive idea since good handplanes are anywhere from very to extremely expensive, and being able to make my own would allow me to build any variation of specialty plane I might want to try. Plus, my CNC router makes forming the basic shapes as easy as digitizing my idea into CAM software. I decided to build a large smoothing plane with a similar approach to the one in the Mike's CNC Shop youtube video. I prepared two planks of white oak a little less than 1.5" thick and drew a basic shape into Cambam.

A closeup of the bed and abutment.

Here are the two halves raw from the router.

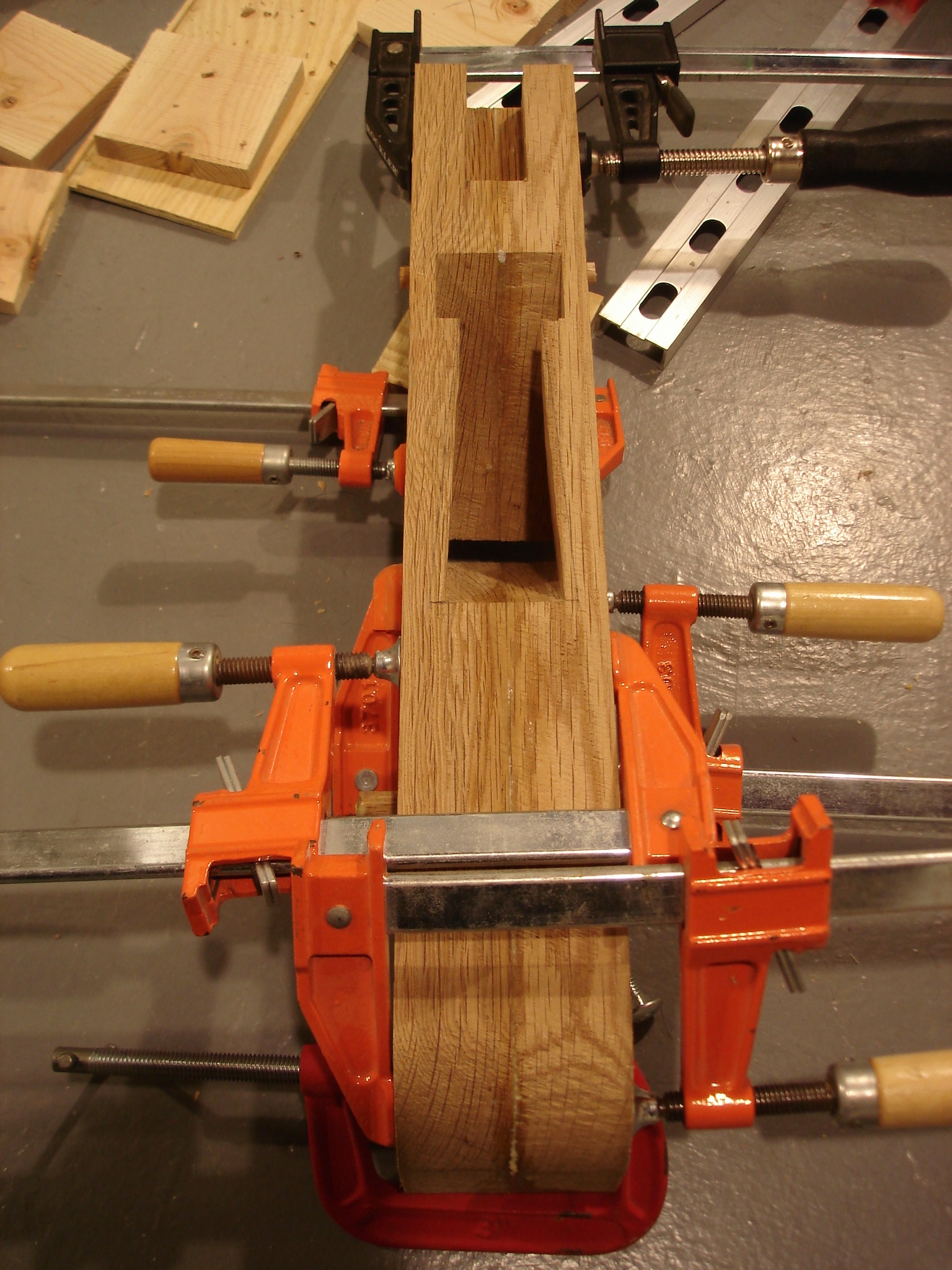

I tapered the abutments to full width at the mouth with hand chisels. I didn't chisel the tapers all the way to the full width at the top-front of the abutments but I'll widen each side with my drill press sander for finger access to the shavings. I clamped the halves together and drilled holes for two dowels that will keep the halves from sliding out of alignment while the glue dries. I tried to keep glue away from the bed but there was a significant amount of squeezeout which I mostly wiped away.

Here is a new 2" iron of A2 tool steel.

The blank for my wedge - rock maple

The high speed steel router bit was fairly dull by the time the mouth halves were cut. The mouth needs some work.

Behold my planemaker's float made from the other half of the wedge blank and a sheet of 80 grit sandpaper

Here is the body cleaned up and sanded a bit.

I traced a diagram of a handle into Inkscape and CNC cut 1in oak.

Here the sanded handle is glued into place. I added a spacer to make room for the iron and wedge to slide in ahead of the handle.

This plane works, but the mouth is huge. I'll build an adjustable mouth.

I CAM'd a 3/8" thick channel and adjustable mouth and aligned the bit to the clamped plane by eye.

The channel for the adjustable mouth

The throat needed a bit of chisel work to accomodate my adjustable mouth.

I planed the stock a little thicker than 3/8" to make sure the mouth piece would start proud of the sole. 80 grit sandpaper on a flat surface flattened the mouth to the sole in just a short time.

The plane can be easily adjusted to make paper thin shavings now. Time for a bit of danish oil.